滤芯扩散流完整性测量仪 测试功能

泡点孔径、气体渗透性、滤芯及设备完整性、折叠滤芯扩散流、耐压测试等。

滤芯扩散流完整性测量仪 技术参数

外形尺寸(mm) | 390?370?170 | 工作介质 | 压缩空气、钢瓶气

| ||

压力量程(kPa) | 50 | 600 | 流量量程 | 20 | 30 |

压力显示精度(kPa) | 0.01 | 0.1 | 流量显示精度(L/min) | 0.1 | |

工作压力(bar) | 0 ~ 6 | 气源压力(bar) | 2.4~8.3 | ||

气源接口(mm) | 6 | 出气接口(mm) | 8 | ||

电压(V) | 220 | 重量(kg) | 5 | ||

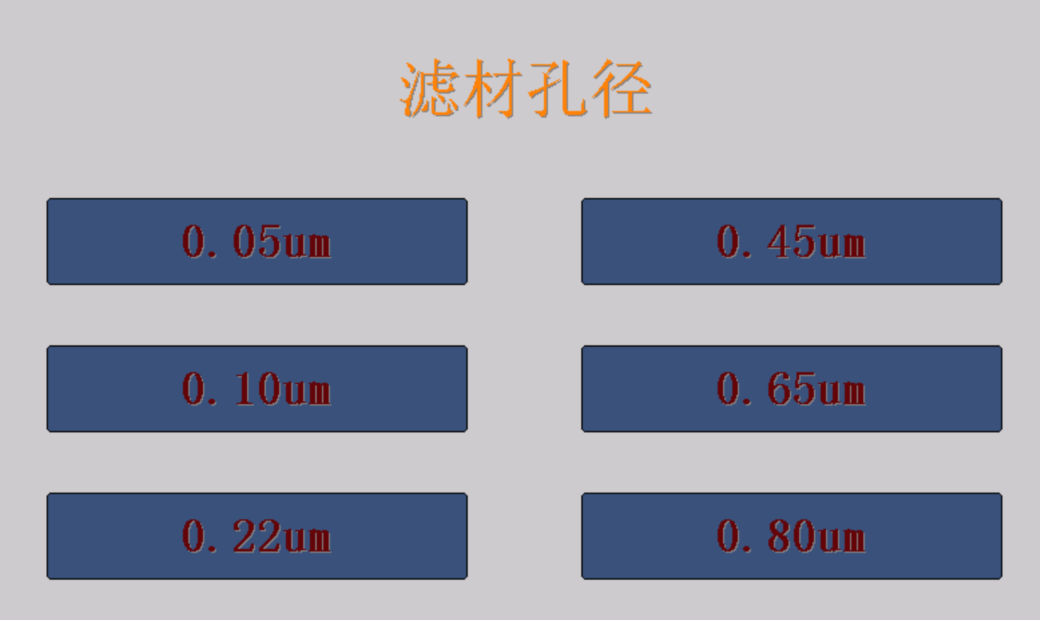

孔径测量范围

润湿剂 | 表面张力(mN/m) | 孔径测试范围(μm) |

去离子水 | 72.8 | 0.4 ~ 500 |

GQ–20 | 20 | 0.1 ~ 100 |

乙醇 | 22.3 | 0.1 ~ 100 |

GQ–16 | 16 | 0.1 ~ 100 |

参考标准:

GB/T5250-1993 可渗透烧结金属材料流体渗透性的测试

GB/T 1969-1996 多孔陶瓷渗透率试验方法

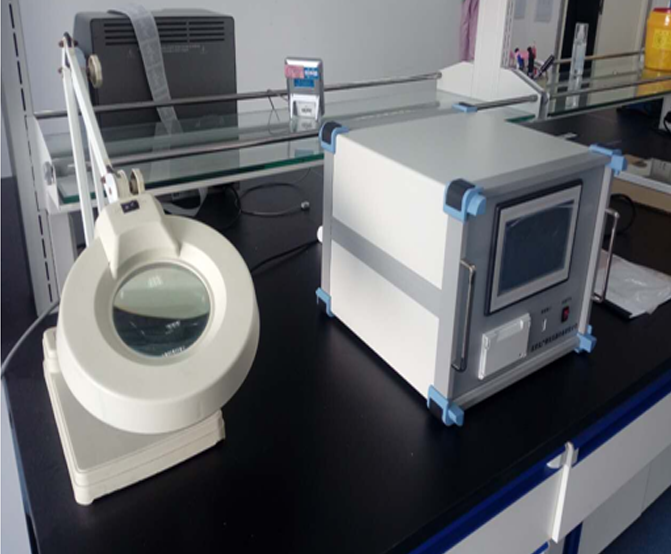

BQS-19 型测试仪采用 5.7″带背光数字液晶显示屏;中文菜单及提示,实时显示测试数 据和曲线,并可打印测试结果及测试曲线,以便监控测试全过程,帮助分析滤膜及过滤系统的性 能;机内大容量存贮空间,可存贮 50 组测试结果及 50 组测试参数。过滤器完整性的全部操作测 试过程仅在过滤器的上游进行,对过滤器的下游无污染,尤其适用于除菌过滤器的检测。

此测试仪可广泛运用于医药、生物工程、食品饮料、微电子等行业,也是过滤器制造商进 行过滤器检测的常规仪器。

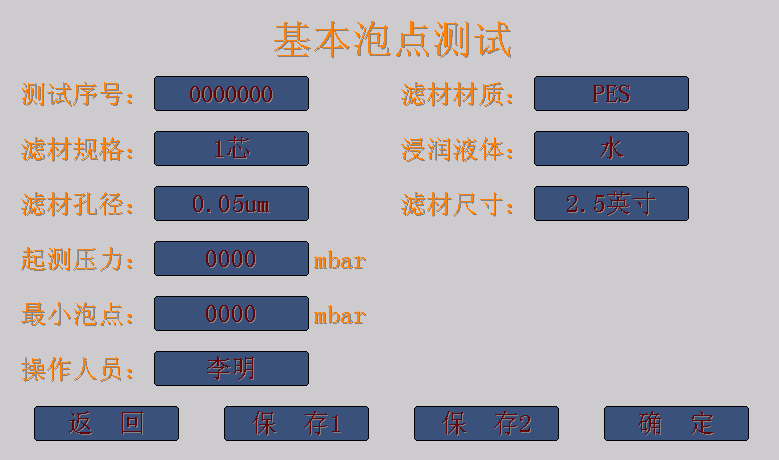

测试原理 1.1 气泡点法

当多孔膜材料被合适的浸润液完全湿润后,由于液体的表面张力和相应毛细管张力的作用, 浸润液充满膜孔并驻留在孔中。在滤材的两侧加上气体压差,要克服毛细管压力将孔道中的液体 赶走而冒出气泡,气体的压差必须增大到某一值?P,这个压差值就称为气泡点,其计算公式如 式 1。式 1 表明,孔径愈小,气泡点愈高,因此可以用气泡点来检测过滤器的性能。

?P=K4σ cosθ / D ( 式 1)

其中: ?P—压差(达因/厘米 2),气泡点值

σ—浸润液的表面张力(达因/厘米)

θ—滤膜与浸润液的接触角

D—孔径(厘米)

K—孔形系数(因为真实的滤膜上的孔不是圆柱形)

滤材被液体(湿润液)浸润后,在滤材的两侧加上气体压差,并使滤材上游成为一个密闭 的气压腔,所加的压差值略小于滤材的气泡点(一般设定在气泡点的 80%),这时气体不能在滤 材的毛细孔中直接流通,但气体分子可以通过毛细孔中的液体扩散至下游,这种由于气体扩散而 形成的气体流量称为扩散流。由于气体的扩散,滤材上游的压力将衰减,衰减值的大小和滤材的 过滤性能形成对应关系,因此测得一定时间内的压力衰减值就能判断过滤器的性能。

1.3 扩散流扩散流与压力衰减值之间存在以下对应关系:

D =??P V / T?Pa (式 2)

其中:D—扩散流值 (毫升/分 ml/min)

?P—压力衰减值(mbar)

V—上游体积(毫升 ml)

T—测试时间(分 min)

Pa—大气压力(1013 mbar)

测得一段时间内的压力衰减值,再测得上游封闭体积后,通过以上公式就可计算得出扩散流值。

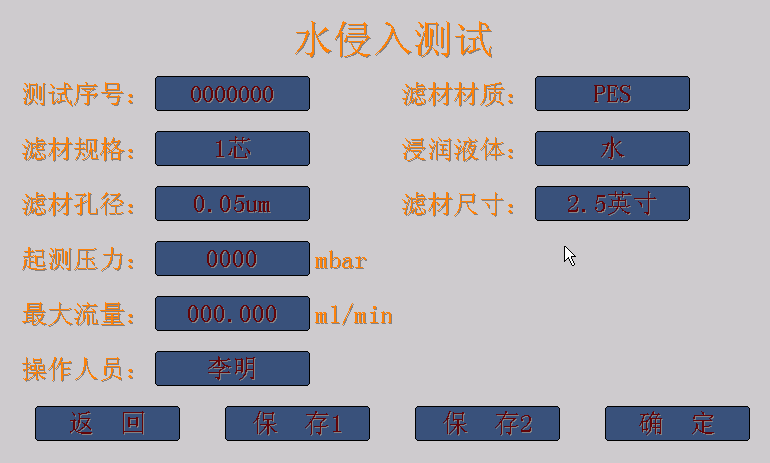

1.4 水侵入保压法这种方法是为测试疏水型筒式滤芯所设计的。目前用前几种方法测试时,对此类滤芯都使 用醇类浸润滤膜。由于醇类的使用会带来健康和可燃性引起的安全性问题,而用水浸入法测试时 只使用去离子水/注射用水(DI/WFI)级别的水,且滤膜不会被湿透,意味着在原理上这是一种 极具吸引力的测试方法。

水侵入保压法的原理是在干燥清洁的疏水性膜上加上水压,表面张力和毛细管张力使水被 排斥,当逐渐升高压力到一定值,水被压过膜上最大孔,此压力值被称为水侵入压力, 当所加水压略低于水侵入压力值,并隔绝上游体积,保持一定时间,使系统稳定,然后测量压力衰减值,将测量值与规定值比较就能判断滤器的完整性,这种方法称为水侵入保压法。

水侵入压力值与膜的孔径、膜的疏水性、水的纯度、水的温度、膜的洁净度、膜的干燥度等有关,影响的因素较多,在实践中要实现这种测试的重现性是很困难的。因此这种方法可作滤 器的粗检,如果水侵入保压法通过,滤器可以使用,如果通不过则用扩散流或保压法进一步进行 验证。

若需进一步的技术支持,请与本公司联系。

Testing function

Bubble point aperture, gas permeability, filter and equipment integrity, folded filter diffusion flow

Voltage withstand test, etc.

technical parameter

Dimensions (mm) 390 ? 370 ? 170 Working medium Compressed air, steel cylinder gas

Pressure range (kPa) 50 600 Flow range 20 30

Pressure display accuracy (kPa) 0.01 0.1 Flow display accuracy (L/min) 0.1

Working pressure (bar) 0~6 Gas source pressure (bar) 2.4~8.3

Air source interface (mm) 6 Air outlet interface (mm) 8

Voltage (V) 220 Weight (kg) 5

Aperture measurement range

Wetting agent surface tension (mN/m) pore size testing range (μ m)

Deionized water 72.8 0.4~500

GQ–20 20 0.1 ~ 100

Ethanol 22.3 0.1~100

GQ–16 16 0.1 ~ 100

Reference standards:

GB/T5250-1993 Test for fluid permeability of permeable sintered metal materials

GB/T 1969-1996 Test Method for Permeability of Porous Ceramics

The BQS-19 tester adopts a 5.7 "backlit digital LCD display screen; Chinese menu and prompts, real-time display of test data and curves, and printing of test results and curves for monitoring the entire testing process, helping to analyze the performance of filter membranes and filtration systems; The large capacity storage space inside the machine can store 50 sets of test results and 50 sets of test parameters. The entire operation testing process for filter integrity is only carried out upstream of the filter, with no contamination downstream of the filter, especially suitable for the detection of sterilization filters.

This tester can be widely used in industries such as medicine, biotechnology, food and beverage, microelectronics, etc. It is also a conventional instrument for filter manufacturers to conduct filter testing.

Testing principle

1.1 Bubble Point Method

After the porous membrane material is completely wetted by a suitable wetting solution, the wetting solution fills the membrane pores and resides in them due to the surface tension of the liquid and the corresponding capillary tension. Adding a gas pressure difference on both sides of the filter material, in order to overcome capillary pressure and drive away the liquid in the channel, bubbles must emerge. The gas pressure difference must increase to a certain value ? P, which is called the bubble point. The calculation formula is shown in Equation 1. Equation 1 indicates that the smaller the aperture, the higher the bubble point, so bubble points can be used to detect the performance of the filter.

? P=K4 σ cos θ/D (Equation 1)

Among them: ? P - pressure difference (dynes/cm2), bubble point value

σ - surface tension of wetting solution (dynes/cm)

θ - Contact angle between filter membrane and infiltration solution

D - Aperture (cm)

K - Pore shape coefficient (because the pores on real filter membranes are not cylindrical)

1.2 Pressure holding method (pressure attenuation)

After the filter material is wetted by a liquid (wetting solution), a gas pressure difference is applied on both sides of the filter material, and a closed pressure chamber is formed upstream of the filter material. The pressure difference applied is slightly smaller than the bubble point of the filter material (usually set at 80% of the bubble point). At this time, gas cannot directly flow through the capillary pores of the filter material, but gas molecules can diffuse downstream through the liquid in the capillary pores. This gas flow rate formed by gas diffusion is called diffusion flow. Due to the diffusion of gas, the pressure upstream of the filter material will decay, and the magnitude of the decay value corresponds to the filtering performance of the filter material. Therefore, measuring the pressure decay value over a certain period of time can determine the performance of the filter.

1.3 Diffusion flow

There is a corresponding relationship between diffusion flow and pressure attenuation values as follows:

D =??P V / T?Pa (Equation 2)

Among them: D - diffusion flow value (ml/min)

? P - pressure attenuation value (mbar)

V - Upstream volume (milliliters/ml)

T - Test time (minutes)

Pa - Atmospheric pressure (1013 mbar)

After measuring the pressure attenuation value over a period of time and measuring the upstream enclosed volume, the diffusion flow value can be calculated using the above formula.

1.4 Water intrusion pressure holding method

This method is designed for testing hydrophobic cylindrical filter cartridges. Currently, when testing with the previous methods, alcohol impregnated filter membranes are used for this type of filter element. Due to the health and safety concerns caused by the use of alcohols, the water immersion method only uses deionized water/injection water (DI/WFI) grade water for testing, and the filter membrane is not soaked, which means that in principle, this is an extremely attractive testing method.

The principle of the water intrusion pressure holding method is to apply water pressure, surface tension, and capillary tension to a dry and clean hydrophobic membrane to repel water. When the pressure gradually increases to a certain value, water is pressed through the maximum hole on the membrane, and this pressure value is called the water intrusion pressure. When the added water pressure is slightly lower than the water intrusion pressure value, the upstream volume is isolated and maintained for a certain period of time to stabilize the system. Then, the pressure attenuation value is measured, and the measured value is compared with the specified value to determine the integrity of the filter. This method is called the water intrusion pressure holding method.

The water intrusion pressure value is related to the pore size, hydrophobicity, purity, temperature, cleanliness, and dryness of the membrane. There are many influencing factors, and it is difficult to achieve reproducibility of this test in practice. Therefore, this method can be used for rough inspection of filters. If water invades and passes through the pressure holding method, the filter can be used. If it fails, diffusion flow or pressure holding method can be used for further verification.

If further technical support is needed, please contact our company.

产品售后服务承诺表述如下:

1.我方对于提供的产品免费保修三年。保修期满后,我方将继续跟踪服务,客户享受终生维修,负责及时提供必要的售后服务、技术咨询。

2.保修期内人为损坏的零部件按采购(加工)价格收费更换。

3.可为用户提供上门服务。

4.提供实时的远程诊断和维护服务。

5.保修期内提供免费的产品软件升级、故障排除、性能调优、技术咨询等售后技术支持服务情况

6.视频指导培训操作人员,使参训人员能正常操作仪器、初步会判断故障、简单维护保养。

7.每年进行客户回访。

8.软件升级:终生免费提供新版本控制软件。

9.提供适用、详细、全面的中文产品说明书和维修手册。

10.提供对故障2小时内响应,24小时内的现场服务。

11.技术支持:对于所需仪器的用户,根据用户的要求提供专业的技术方案。除了常规的仪器服务外,我公司技术部还可为用户提供各种非常规设备的技术支持。

关于仪器质保:1、北广仪器保证提供的设备为需方指定的全新设备,其各项技术指标均符合相关的产品技术要求。2、设备经客户验收合格后,开始计算保修期,设备免费保修期为壹年,设备在质量保质期内,产品在非人为损坏的情况下,由北广仪器负责全保。北广仪器的客服在得到通知后24小时内响应,安排约定维修细节。3、质保期后,我们免费为您维修维护设备,除大型设备外所有设备一律返厂维修,经检验后,电话告知客户问题所在及解决方式,经客户同意后进行维修,维修后发回客户,对于损坏及更换的零部件我们只收取成本费;如客户不认同我们的检验结果,双方另协商维修细节。